Better Touch Better Business

Contact Sales at Gladman Iron Doors

The method of jointing the scrolls depends on the material, size, thickness and complication of the scrolls. Different kinds of preparation should be made according to the specific requirements of the procedure, like clearing the splotch, inserting the sandblast and preheating.

Gladman usually use welding to joint the various scrolls, so it goes to welding again, just the issue the former article “About Welding” said. Welding methods include gas welding, brazing, manual arc welding, and manual electrostatic welding. Among them, gas welding is divided into hot welding, heating reduction zone method, and non-preheating gas welding; manual arc welding is divided into cold welding, semi-hot welding, non-preheating welding and hot welding.

Hot cracking: When the welding stress exceeds the strength of the cast scrolls, the joint area along the weak area or fusion area will peel the joint point. To prevent the cracks like these, we usually get down to decrease the stress:

1) Adopting the thermal welding method: Preheating the the scroll to 600-700°C, and keep the temperature on above 40°C throughout the whole welding process;

2) Applying the heating reduction area method: Selecting the correct heating point and way to heat the cast scroll, so that the increasing gap can be welded into a perfect scroll as the drawing said;

3) Using the correct arc when cold welding: Changing the chemical composition and alloy system of the cracks to get better performance and lower hardness.

Hot cracks are always perpendicular to the weld scale pattern, with longitudinal, oblique or transverse directions, owing to the increased content of carbon, sulfur, phosphorus and silicon in the cracks. The ways to prevent such a problem are as follows:

1) improving the thermal crack resistance of the electrode and choosing alkaline low-hydrogen electrode. The solutions to the former issue are mainly about enhancing the alkalinity of the coating, reducing the content of sulfur and phosphorus, adding materials with strong desulfurization ability, such as rare earth, ferromanganese;

2) Using a smaller current to reduce the penetration depth, tilt the position of the weld, and use vertical or semi- vertical welding to speed up the welding speed.

Welding Steps

1. Selecting welding method according to product drawings, technical limitation, product lot and required date, and taking the realistic condition of the factory into consideration.

2. Drawing the process symbols on each view of the cast welding.

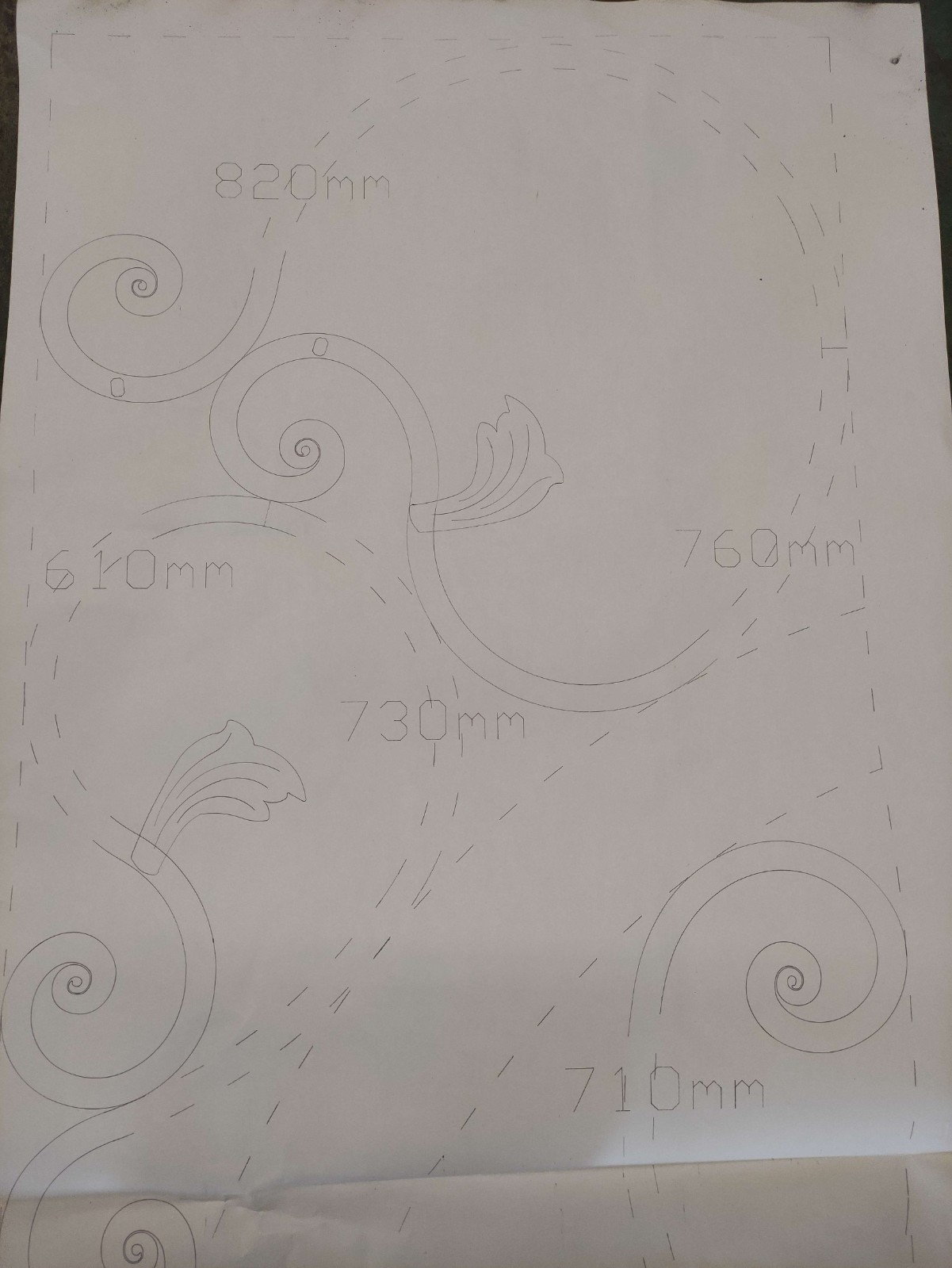

Drawing the position, shape, size and quantity of the gating system for regular and sample welding.

3. Marking the draft angle of the wall perpendicular to the parting surface.

4. Marking the cast iron welding pouring position and parting surface.

5. Drawing the shape of the sand core, the sand core block line (including the negative number of the core), the core head gap, the compression ring and the anti-pressure ring, and the sand groove; and marking the relevant size and the negative of the sand core, and design the shape, size and amount of sand eaten if necessary.

6. Analyzing the structural manufacturability of castings; determining the tendency of defects; putting forward structural improvement opinions and determining the principle of solidification of cast iron welding.

Precautions

1. The length of the arc

The length of the arc is related to the type of electrode coating and the thickness of the coating. However, short arcs should be adopted as much as possible, especially low-hydrogen electrodes. Long arcs may cause blowholes. The short arc can prevent harmful gases such as O2 and N2 in the atmosphere from invading the weld metal, forming oxides and other undesirable impurities, which will affect the quality of the weld.

2. Welding speed

The appropriate welding speed is based on the corresponding changes in conditions such as the diameter of the electrode, the type of coating, the welding current, the heat capacity of the welded object, and the beginning of the structure, which cannot be specified in the standard. Keep the proper welding speed, the molten slag can cover the molten pool well. Make the various impurities and gases in the molten pool have sufficient time to float out, and avoid the formation of slag and pores in the weld. When the welding speed is too fast, the shrinkage stress will increase when the welding part cools, causing cracks in the welding seam.

Key points of welding wire selection

The selection of welding wire should be based on comprehensive considerations such as the type of steel, the quality, the welding conditions and cost of the welding parts.

The order when selecting the welding wire is as follows:

①According to the type of the steel to be welded, selecting the welding wire that meets the requirements of mechanical properties or heat resistance and corrosion resistance.

②According to the quality requirements of the welded parts, choose the welding wire to achieve the maximum efficiency and reduce cost of welding materials.

③According to the welding position, corresponding to the thickness of the workpiece to be welded and the current value used, select the welding wire grade suitable for the welding position and use current.