Better Touch Better Business

Contact Sales at Gladman Iron Doors

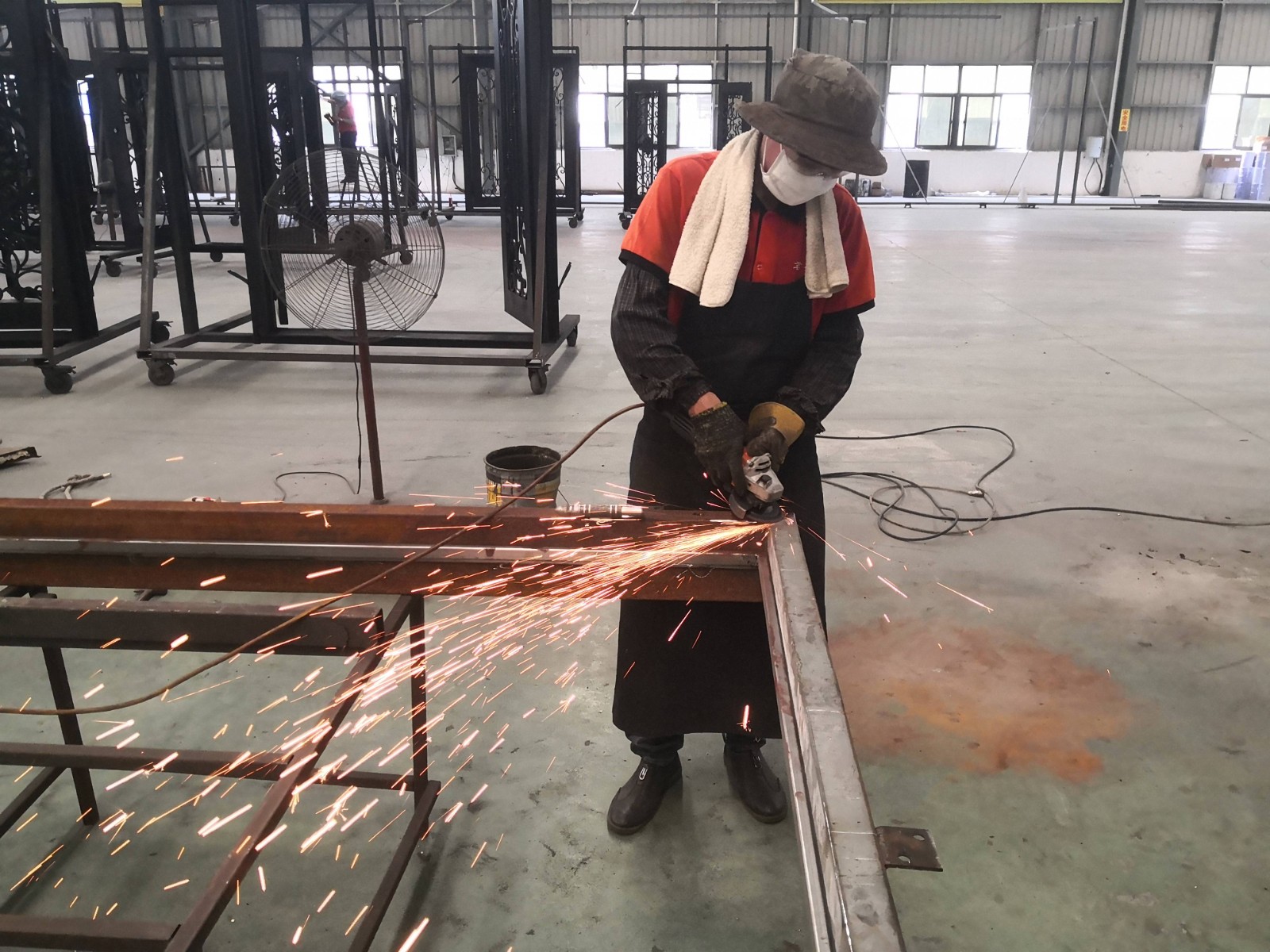

After shaping the door frame, there will be several welding dots on the surface affecting the whole beauty of the door. Therefore, polishing is necessary. The angle grinder is the common tool in this process and it is also the theme of this article. Angle grinder, also known as grinder or disc grinder, is a kind of abrasive tool used for cutting and grinding glass fiber reinforced plastic. It is mainly used for cutting, grinding and brushing metals and stones.

Principle

Electric angle grinder takes the advantages of high-speed rotating sheet grinding wheels, rubber grinding wheels, steel wire wheels, etc. to grind, cut, rust, and polish metal components. Angle grinders are suitable for cutting, grinding and brushing metals and stones. Do not use water during operation. A guide plate must be used when cutting stone. For models equipped with electronic control devices, if suitable accessories are installed on this type of machine, grinding and polishing operations can also be carried out.

It should be noted that the angle grinder is used for polishing, because the angle grinder has a high speed, using a cutting blade or saw blade, and when cutting the blade, you should not take a sharp turn or use too much force to cut hard materials with a thickness of more than 20mm. Otherwise, once it gets stuck, it will cause the saw blades and cutting blades to shatter and splash, or the machine bounces out of control, which may damage the goods, or hurt people! Please choose a high-quality saw blade with more than 40 teeth, and operate with both hands, and take protective measures .

Operating procedures

Operating procedures

Angle grinder is an abrasive tool used for cutting and polishing. Lightweight multi-purpose angle grinder, suitable for deburring and polishing.

1. Wear protective goggles.

2. After turning on the switch, wait for 3~5 minutes and observe the stable rotation of the grinding wheel before working.

3. Workers with long hair must tie up their hair first.

4. Do not turn the direction towards the person.

5. After working continuously for half an hour, stop for fifteen minutes.

6. Do not hold small parts on your hands when working.

7. Consciously clean the working environment after the work is completed.

Maintenance

Small angle grinders are electric tools that we often use in our daily lives, so the often maintenance of them is necessary.

1. Frequently check whether the power cord is firmly connected, whether the plug is loose, and whether the switch action is flexible and reliable.

2. Check whether the brushes are severely wore, and replace the brushes in time to prevent excessive sparks or burning of the armature due to poor contact of the brushes.

3. Pay attention to check that the inlet and outlet of the tool should not be blocked, and remove the oil and dust from any part of the tool.

4. Grease should be added in time.

5. If the tool fails, send it to the manufacturer or the designated maintenance center for repair. If the tool is damaged due to abnormal use or man-made wrong disassembly and repair, the manufacturer generally does not repair or exchange it free of charge.

6. Check the shortcomings of angle grinders. There are two kinds of inspection methods: visual inspection, which directly observes whether there are cracks on the surface of the angle grinder; percussion inspection, which inspects the inside of the main angle grinder, is to hit the angle grinder with a mallet. If there is no problem with the angle grinder, it should be a crisp sound, if it is other sound, it indicates a problem.

7. Check the rotation strength. Even in the same type or batch, each of the angle grinders should be inspected before installation and use.