Better Touch Better Business

Contact Sales at Gladman Iron Doors

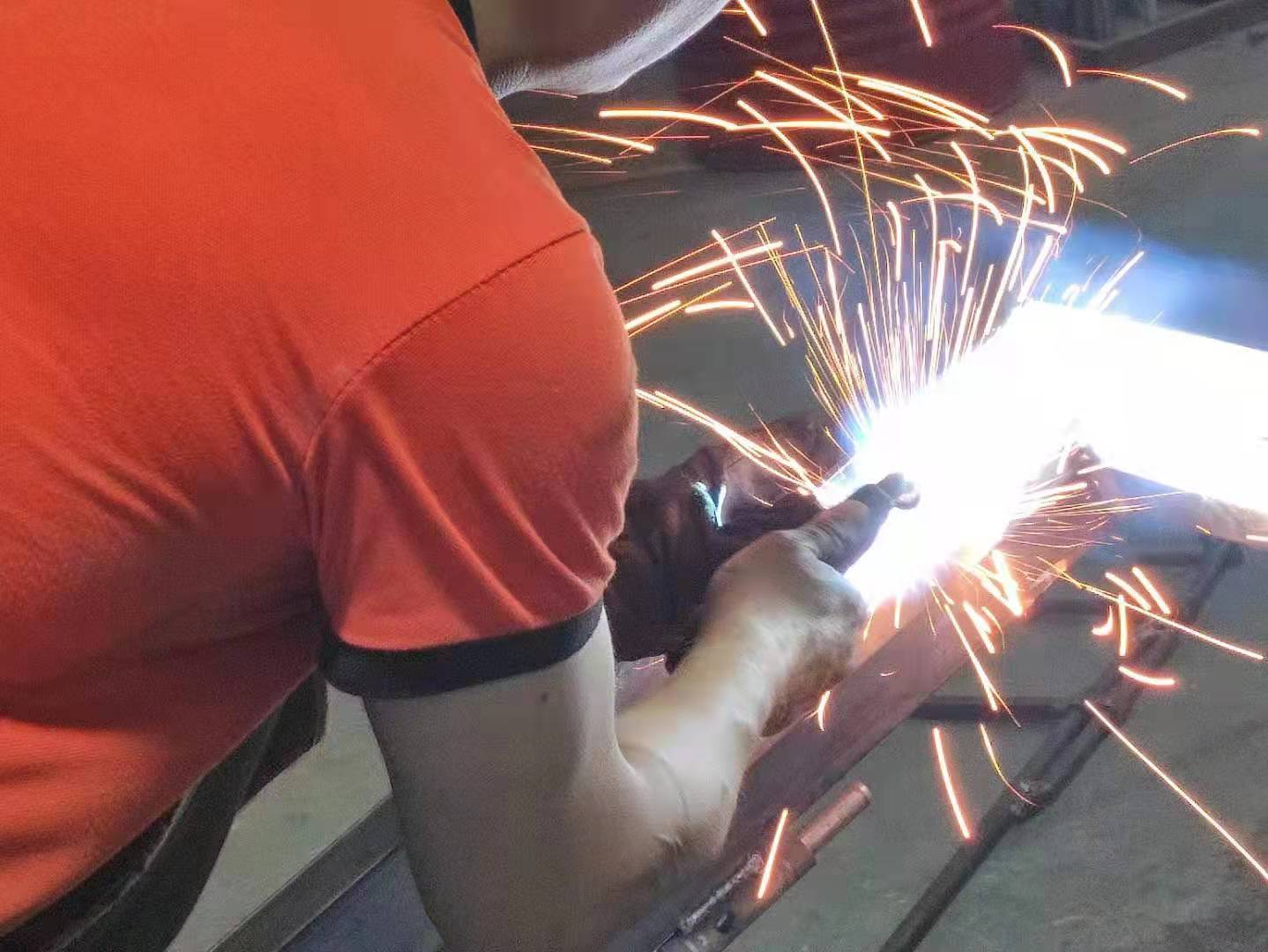

There are many energy sources for modern welding, including gas flames, electric arcs, lasers, electron beams, friction and ultrasound. In addition to being used in factories, welding can also be carried out in a variety of environments, such as the field, underwater and space. No matter where it is, welding may bring danger to the operator, so appropriate protective measures must be taken when welding.

There are many energy sources for modern welding, including gas flames, electric arcs, lasers, electron beams, friction and ultrasound. In addition to being used in factories, welding can also be carried out in a variety of environments, such as the field, underwater and space. No matter where it is, welding may bring danger to the operator, so appropriate protective measures must be taken when welding.

The development of welding technology in recent years includes: electron beam welding in 1958 can heat a small area, making it possible to weld deep and narrow workpieces. Later, laser welding was invented in 1960, and in the following decades, it proved to be the most effective high-speed automatic welding technology. However, the two technologies of electron beam welding and laser welding are limited in their application scope due to the high cost of the equipment required.

Welding purpose

Welding achieves the purpose of joining through the following three ways:

1. Fusion welding-heat the workpiece to be joined to partially melt it to form a molten pool. The molten pool will be joined after cooling and solidification. If necessary, a filler can be added to assist. It is suitable to weld various metals and alloys.

2. Pressure welding-the welding process must apply pressure to the materials, which belongs to the processing of all kinds of or partial metal materials.

3. Brazing-use a metal material with a lower melting point than the base material as the brazing filler metal, use the liquid brazing filler metal to wet the base metal, fill the joint gap, and mutually diffuse with the base metal to realize the connection of the weldment. It is suitable for all kinds of various materials, and also for different materials.

During the welding process, the workpiece and the solder are melted to form a molten area, and the connection between the materials is formed after the molten pool is cooled and solidified. During this process, pressure is usually applied. Today, with the widespread application of welding robots in industry, researchers are still studying the essence of welding and continue to develop new welding methods to further improve welding quality.

Characteristics of welding structure

1. Machinery

The spot welding machine system is composed of three parts: mechanical device, power supply device, and control device. In order to meet the welding requirements, the pressure (welding tongs) adopts a double-stroke fast pneumatic transmission mechanism. The opening degree of the welding clamp can be changed by switching the stroke control handle. It can be divided into large opening and small opening to meet the welding requirements. The normal state is that the welding tongs are opened for a short stroke. When the control button is switched to the "power on", the tongs will be clamped and pressurized. At the same time, the current returns to the short stroke after completing a welding cycle under the control of the control system.

2. Power supply device

The main power circuit is composed of resistance welding transformer, thyristor unit, main power switch, welding circuit, etc. The welding equipment we use is a single-phase power frequency AC resistance welding machine with a power of 200kVA and a secondary output voltage of 20V. Due to the production of multiple models in the same line, the welding tongs need to concurrently weld high-strength steel plates and low-carbon steel sheets, and the gun arms of the welding tongs must transmit large mechanical force and welding current. Therefore, the strength, rigidity and heat generation of the welding tongs must meet certain requirements. And it must have good electrical and thermal conductivity. At the same time, the welding tongs are usually cooled by water.

3. Control device

The control device mainly provides signals to control the action of the welding machine, control the welding current value, and perform fault monitoring and processing.

Precautions

1. The length of the arc

The length of the arc is related to the type of electrode coating and the thickness of the coating. However, short arcs should be adopted as much as possible, especially low-hydrogen electrodes. Long arcs may cause blowholes. The short arc can prevent harmful gases such as O2 and N2 in the atmosphere from invading the weld metal, forming oxides and other undesirable impurities, which will affect the quality of the weld.

2. Welding speed

The appropriate welding speed is based on the corresponding changes in conditions such as the diameter of the electrode, the type of coating, the welding current, the heat capacity of the welded object, and the beginning of the structure, which cannot be specified in the standard. Keep the proper welding speed, the molten slag can cover the molten pool well. Make the various impurities and gases in the molten pool have sufficient time to float out, and avoid the formation of slag and pores in the weld. When the welding speed is too fast, the shrinkage stress will increase when the welding part cools, causing cracks in the welding seam.