Better Touch Better Business

Contact Sales at Gladman Iron Doors

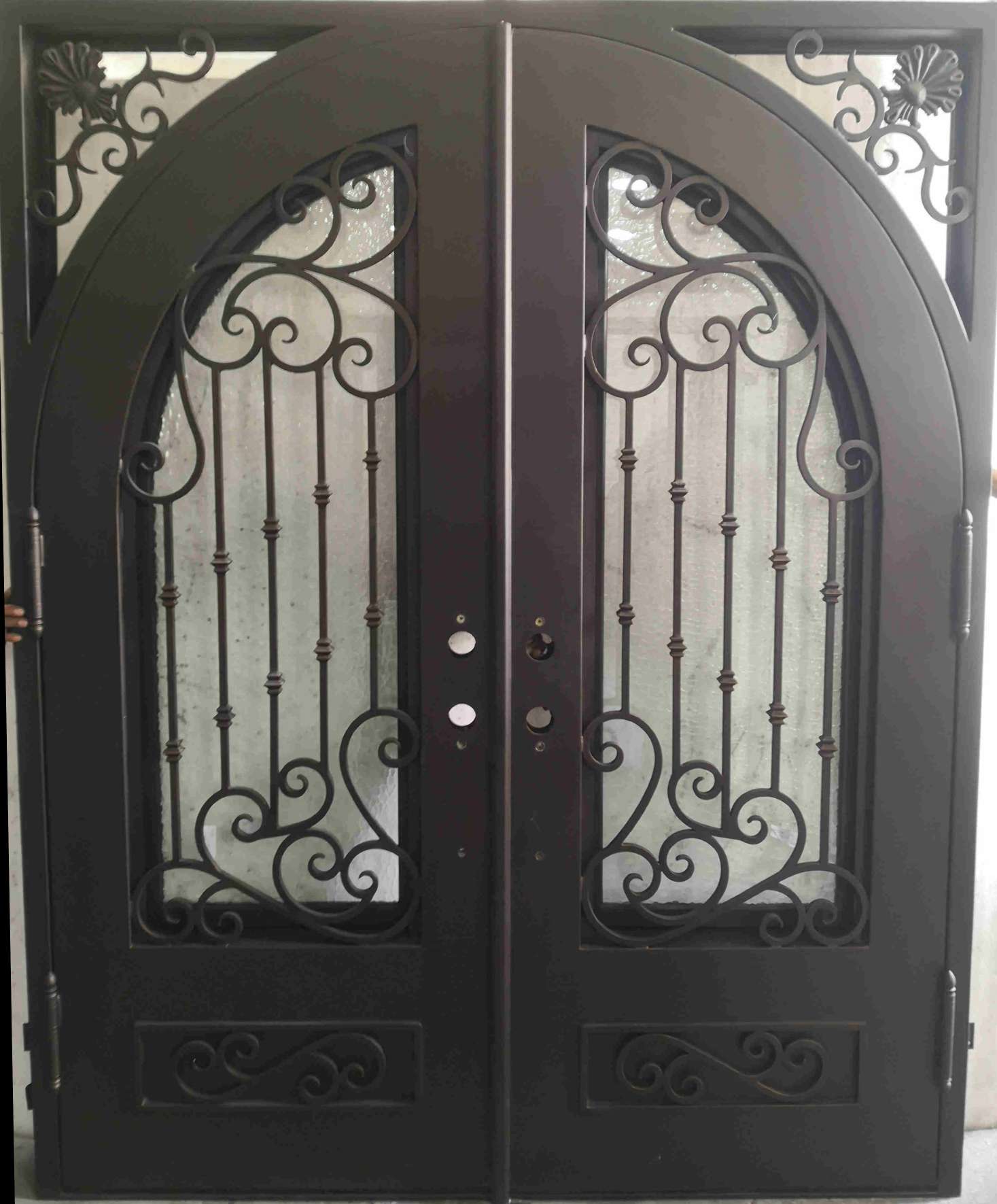

As a key step in production, adjusting the door is the end of the previous process and the beginning of the post process. Due to different designs, the door frame and door leaf are produced separately according to the drawings, so in the door adjustment stage, the door frame and door leaf ushered in the first integration. And because of the separate production, there will inevitably be some manual errors between them, so the door adjustment becomes the link between the previous process and the post process-the mismatch between the door frame and the door leaf will disappear here.

Adjust the door, the last step of the previous process, after sandblasting and zinc blasting, it will appear silvery gray. The tools for adjusting the door are basically a crowbar and a screwdriver. You can use these two tools to adjust the door if the gap is too large or the door is a bit crooked. Before the door leaf is connected to the door frame, the worker will cut a keyhole in the door leaf. If the product is a hurricane door, there will be a small step of welding the hurricane bolt in this step. If you find a problem that is difficult to adjust at this step, such as the wrong direction of opening the door, you need to rework. Because the wrong direction of opening the door means that the position of the door wheel and keyhole and other accessories need to be adjusted, and these adjustments require electric welding, cutting and welding, and it is impossible to complete with a screwdriver and a crowbar alone.

Under normal circumstances, the following aspects should be checked when adjusting the door:

(1) Door frame inspection: Whether the door frame is installed firmly and smoothly, whether the connection between the door frame and the wall is tight, and whether there are abnormal burrs, cracks, damage, etc. on the surface of the door frame;

(2) Door leaf inspection: Whether the door leaf is deformed or cracked, whether the appearance of the finish paint is intact, whether the surface is smooth, whether there are obvious scratches, bumps, and whether the ground decoration method should be reserved for the distance from the ground;

(3) Door lock inspection: Whether the door lock is installed firmly, whether the key is smoothly inserted and removed, whether the lock core rotates freely, whether the lock tongue is retractable in all directions, and whether the keyhole position is normal;

(4) Opening inspection: Whether the door opens and closes smoothly, whether there is abnormal resistance, and wear, whether there is shaking after the door is locked;

(5) Door handle inspection: whether the installation is firm, whether there is abnormal resistance when rotating, whether the surface is defective or deformed;

(6) Sealing inspection: Whether the seam of the door leaf is within 2.5mm.

If all goes well during the door adjustment process, the door frame and door leaf will be unloaded and sent to the next process-making up the putty. At this time, the previous process of production is over.