WROUGHT IRON DOORS

Blaenavon History And The New Age of Steel

by:Gladman

2020-08-31

When considering Blaenavon history, most people think of coal mines and iron works, and while it is true that coal was mined at Blaenavon (to feed the furnaces), and that the town's ironworks was at one time world-famous (and in certain ways still is), it is in the history of steel development that the town deserves its highest accolade.

For a small town lying half way up a Welsh mountain, Blaenavon has achieved a lot. Unfortunately, however, steel chemistry isn't sexy enough to get the historians and the press too excited, and a lack of informed chemical knowledge leaves the town known only for its iron heritage and perhaps the confused belief that it somehow had something to do with phosphorus-free iron.

Close, but not close enough, and the record should be put straight to give this small Welsh eastern valley town the position in history that it deserves. Blaenavon history is not just restricted to iron, but to the development of steel, the alloy that changed the nature of 19th and 20th century industry and warfare.

Before discussing the town's rightful place in the 19th century steel industry that was recognized even by Andrew Carnegie, it should be stressed that Blaenavon's industrial landscape thoroughly deserves its World Heritage status, an accolade awarded to the town by UNESCO in December, 2000.

It is also true that that this recognition was given to the landscape around the town created by the collieries and iron ore workings, the whole purpose of which were to feed Blaenavon Iron Works that produced much of Britain's iron during the 19th century. Blaenavon history is steeped in the iron and steel industry, not coal that many wrongly believe to have been its staple product.

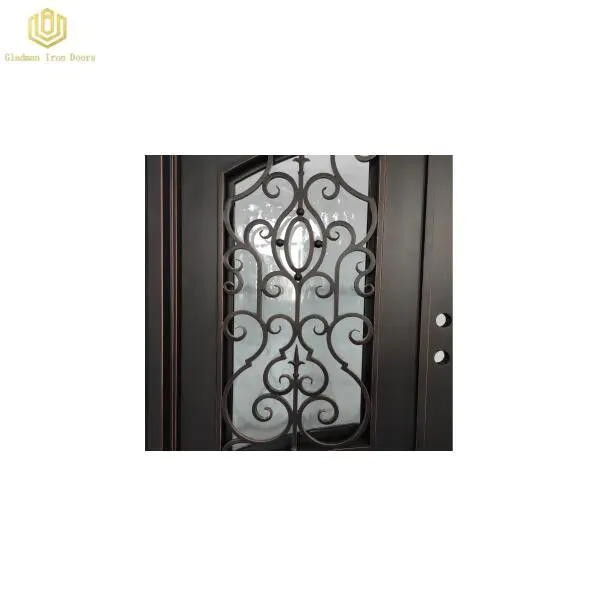

Not only was the Blaenavon used to lay the tracks for railways worldwide, but also to provide the railings, gates and even the window frames of St. Peter's Church, built in 1804 and consecrated in June 1805. This small town not only enjoys UNESCO recognition, but St. Peter's has been honoured by two visits by the Archbishop of Canterbury over the past decade: once for the induction of the current vicar, reverend Jason Bray, and later on Palm Sunday, 2005, for the 200th anniversary of the church.

However, I digress, the point here being that although Blaenavon has enjoyed the fame that she thoroughly deserves, the town has not been properly recognized for the part she played in the development of modern steel. Here is a brief synopsis of the story of steel and why Blaenavon history is rich in the influence the town had over UK industrial development for over 100 years.

Steel is produced by combining iron and carbon in defined quantities: from 0.25 to 1.5% iron depending on the grade of steel required. Iron normally contains more carbon that this, so Henry Bessemer invented a process whereby air was blown through molten iron to oxidize the carbon to its oxides, carbon monoxide and carbon dioxide that was released into the atmosphere.

Carbon could then be added to the molten iron in the correct quantities to form the required grade of steel. An amusing aside is that in today's controlled industrial environment, the process would likely have been disallowed for being responsible for too many carbon emissions into the atmosphere. It's as well that steel was already developed before today's bureaucrats became involved!

One major problem was the natural phosphorus contained in iron ore that could not be removed by normal smelting techniques. Phosphorus renders steel too brittle for major construction use. To cut a long story short, a young chemist by the name of Sidney Gilchrist Thomas developed a method of removing the phosphorus during the steel manufacturing process.

He did this by adding lime to the carbon and iron mix that reacted with the phosphorus, forming calcium phosphate. This rose to the top of the furnace as a slag which was then skimmed off - a bonus of this process being a phosphate fertilizer that was sold to provide the Blaenavon Company with even more profit! The production tests for this process, known as the Thomas Process, were carried out in Blaenavon using a Bessemer converter purchased by the Blaenavon Company for the purpose.

The development of high grade steel, therefore, is one of the major highlights of Blaenavon history. The new age of steel was enabled through the willingness of the Blaenavon Company to offer Gilchrist Thomas the equipment for his tests, although there is a twist to this particular tale.

The new Thomas process enabled poor quality iron to be used to make steel cheaply, which opened the door for large scale steel production in Europe and the USA which was not possible until then. This led to the demise of Blaenavon ironworks that lasted only 25 years after Sidney Gilchrist Thomas unwittingly signed its death warrant by opening high grade steel production to the massive iron foundries of the world with which Blaenavon could not compete.

Biter bit, hoist on his own petard or whatever term you wish to use. By making steel easier to produce, Blaenavon ironworks destroyed itself. In the words of Sir Michael Caine - 'not a lot of people know that!'

Custom message